Antibody

QYAOBIO provides custom antibodies for customers in worldwide

Antibody production is the biological process, the immune system generates specialized proteins(antibodies) in response to the foreign substances, like pathogens, antigens. These antibodies play the critical role in the defense mechanism of immune system, they can recognize and bind to specific antigens, and mark for destruction or neutralization.

The optimization of antibody production is focusing on yield enhancement, antibody expression improvement, downstream process streamline. Antibody production has the crucial role in advancements of diagnostics, therapeutics, and scientific research. QYAOBIO, as the custom antibody supplier, provides comprehensive antibody development and production services, from antigen design to custom antibody generation.

PUBLIC SERVICE

Antibody Production Process

Antibody production process involves the entire procedures of producing the antibody with specificity to distinct biological targets. In brief, the general steps:

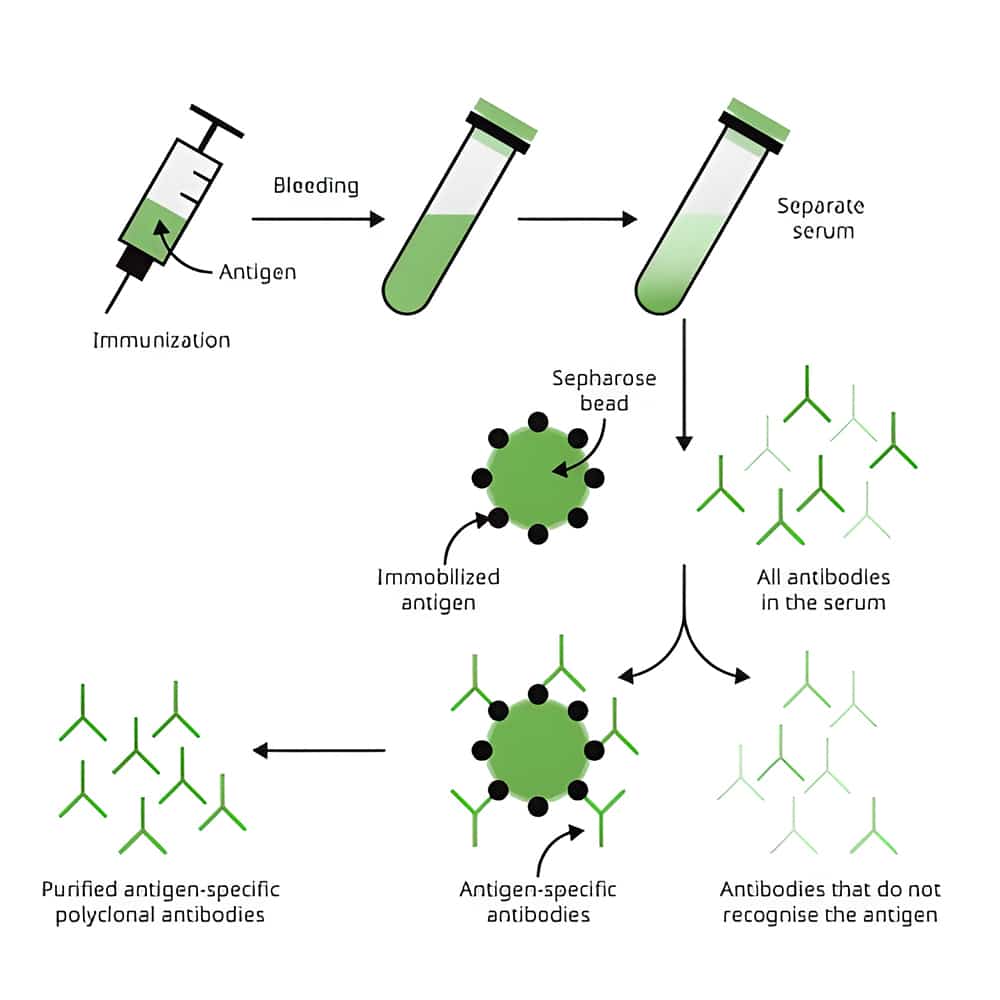

Polyclonal Antibody Production

Polyclonal antibodies are the heterogeneous mix of antibodies, each antibody can recognize different epitopes of a particular antigen. Polyclonal antibody production typically starts with immunization with the target antigen, to stimulate the immune respons, then produce the antigen-specific antibodies by B cells. The immunizations of the same antigen will repeat at intervals of several weeks, in order to increase the number and affinity of antigen-specific antibodies. The resulting immune-sera with antibodies can be used in crude form, or isolated by affinity purification.

Polyclonal antibodies are the mixture of antibodies with natural immune response to the antigen. Therefore, they can create a strong signal against the target antigen in relevant application, and not against a single epitope. However, the main disadvantages of polyclonal antibodies are limited in supply, and higher variation in batch-to-batch.

In addition, polyclonal antibodies exhibit cross-reactivity and less specificity, due to the higher risk of binding to proteins with similar sequences. These issues are usually solved by cross-adsorbing antibody mixture to remove antibodies with unwanted binding characteristics.

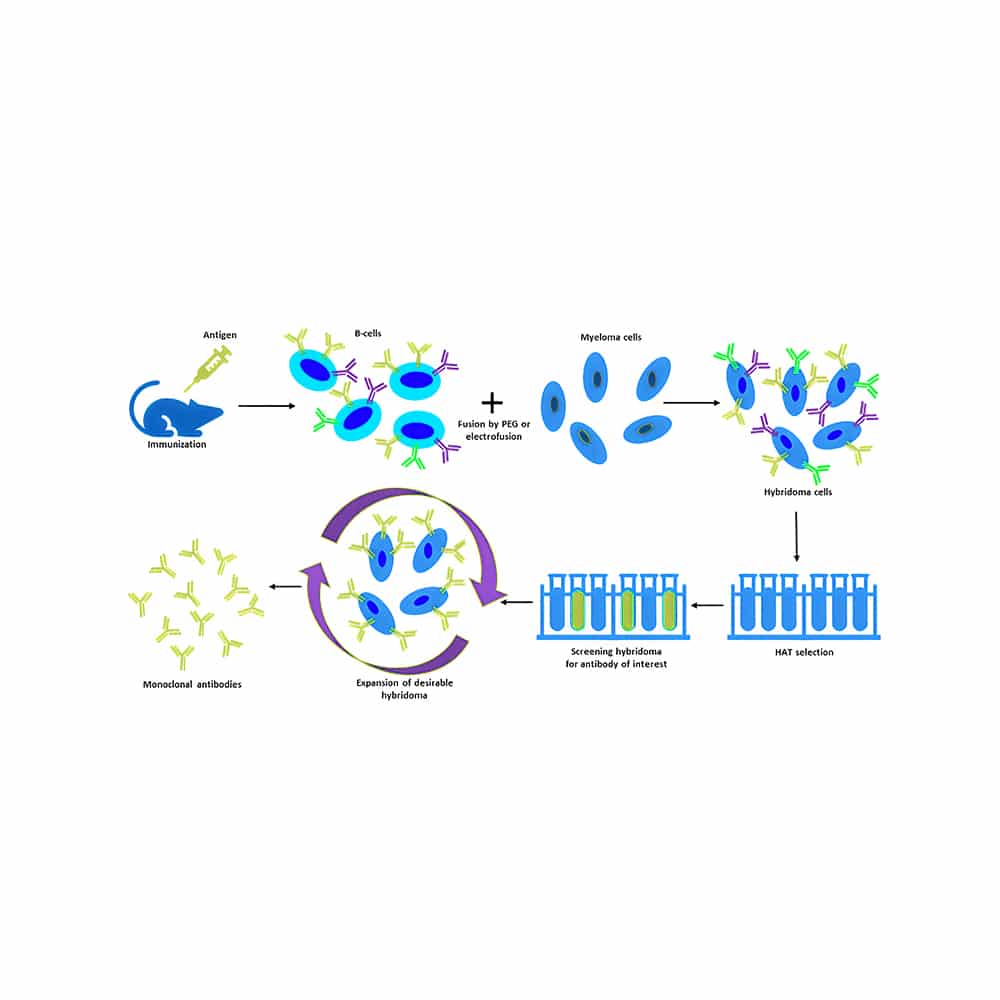

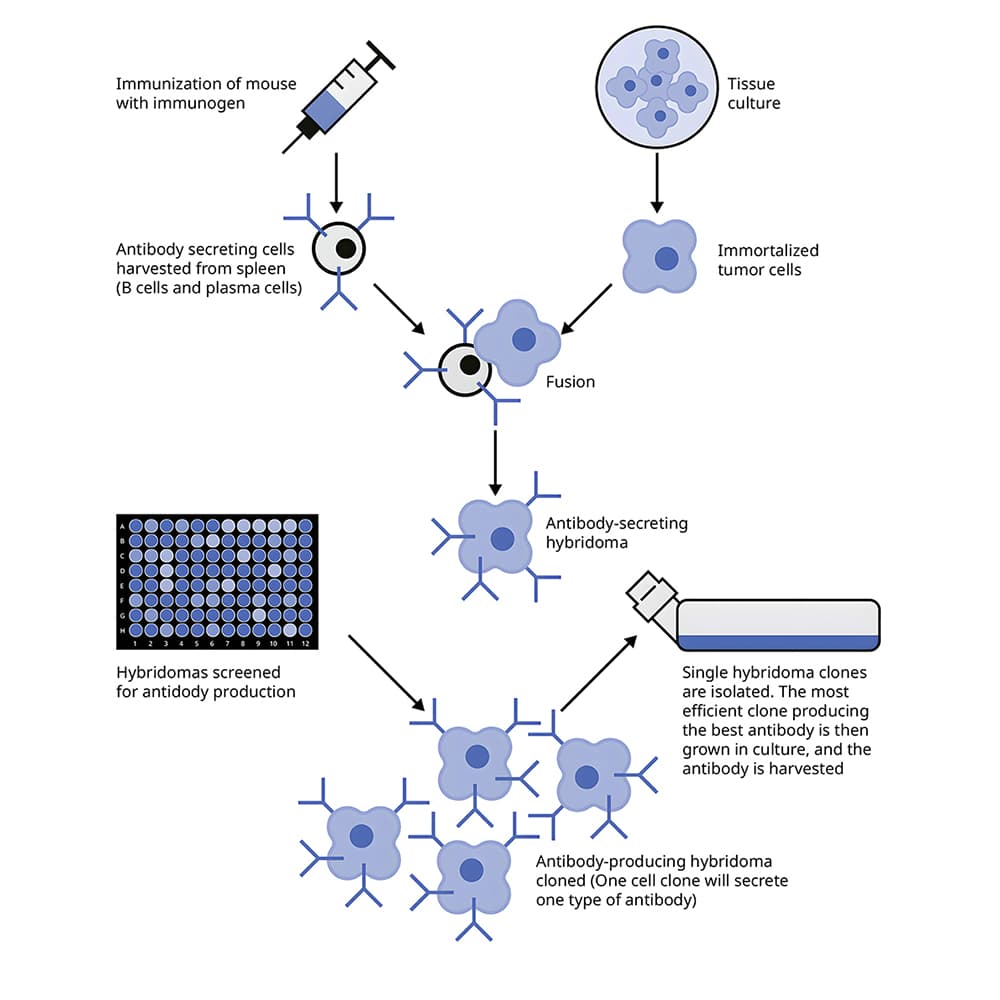

Monoclonal Antibody Production

Monoclonal antibody production generates identical antibodies, each antibody is designed to bind the single epitope to an antigen. Comparing to polyclonal antibodies, the monoclonal antibody is derived form a single B cell parent, it will only recognize the single epitope per antigen.

There are different technologies feasable for monoclonal antibody production, such as the hybridoma technique, the single b-cell method, the phase display. Although the broad variety of production methods, each is designed to generate homogenous-monoclonal-antibodies. Monoclonal antibodies are highly specific and uniform, this is valuable for various medical and research applications, like diagnostics and targeted therapies.

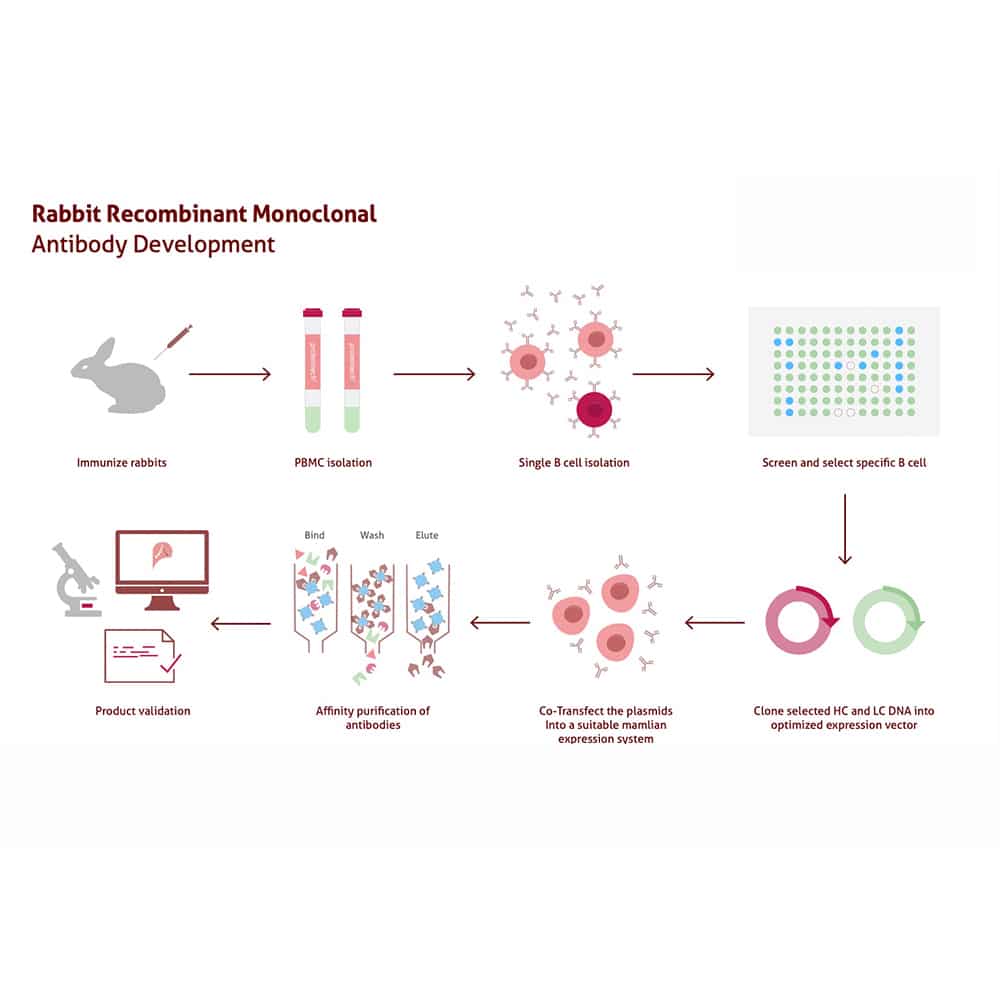

Recombinant Antibody Production

Recombinant antibody production applies genetic engineering to create antibodies. Firstly, isolate and clone the antibody genes into expression vectors. Then introduce into the host cells, such as bacteria or mammalian cells. Lastly, the host cells generate the recombinant antibodies, which can be harvested and purified.

This production technology has precise control over antibody properties. It is essential for the generation of therapeutic antibodies, diagnostics, and research tools. In order to generate custom antibodies with custom characteristics for specific applications.

Antibody Production Techniques

In vivo & in vitro are two key techniques in antibody production, the major different between these two techniques: in vivo antibody production involves the application of living animals, while in vitro is performed by cell culture in labs.

In Vivo Antibody Production Techniques

Animal Immunization

Apply animals to immunize with antigens, in order to stimulate antibody production. This method results in the mix of both ployclonal and monoclonal antibodies.

Hybridoma Technology

Hybridoma technology can generate monoclonal antibodies by fusing immune cells with myeloma cells. This method provides consistent monoclonal antibodies with specific antigen recognition.

Monoclonal Production in Vivo

Animals with hybridoma cells produce monoclonal antibodies in bodies, collected from the ascites fluid.

In Vitro Antibody Production Techniques

Recombinant DNA Technology

Clone and express antibody genes into host systems (bacteria, mammalian cells), in order to achieve controlled antibody production.

Phase Display

Bacteriophages with engineered genes display antibody fragments, this technique will enable targeted antibody selection and optimization without animal immunization.

Mammalian Cell Expression

CHO cells in mammalians are applied for large-scale & controlled antibody production with post-translational modifications.

The selection of ideal antibody production methods depend on different factors, each techniques have the unique advantages and disadvantages.

Challenges in Antibody Production

There are several challenges to ensure efficient and reliable antibody production. The variability in antibody yield and quality are raised from cell line heterogeneity, culture conditions, and purification techniques. Optimization of timelines and costs is another challenge, we need to achieve the balance between high yields, quality, and cost-effectiveness.

In addition, scaling-up production from laboratory to industrial-scales also presents new difficulties, this requires careful optimization of culture conditions and purification methods.

Optimize Antibody Production

Recombinant antibody production techniques can address challenges effectively, particularly by applying Chinese Hamster Ovarian (CHO) cells. CHO cells provide a scalable and reliable platform for efficient, stable antibody production with low variability. CHO antibody production enables fast production timelines from laboratory to industrial scale, and also optimize culture conditions and purification methods. Moreover, it also eliminates ethical considerations without animal-based methods.

However, the choice of antibody production technology depends the specific requirements. Different antibody formats and characteristics require alternative approaches. Our researchers must evaluate the requirements carefully, and select the appropriate technology to ensure optimal results. Continual advancement in innovative strategies and technologies, will overcome challenges and drive the field forward in antibody production, particularly in recombinant antibody production.

Call Us

+86(021)-50795728

+86(027)-60707970