Recombinant Antibody Production

QYAOBIO provides different recombinant antibody production for customers in worldwide

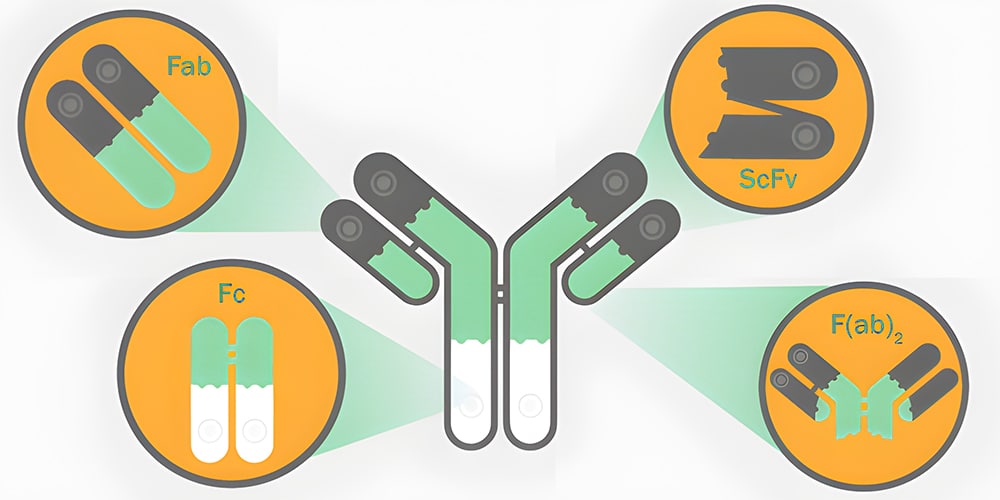

Recombinant antibodies (rAbs) are a type of monoclonal antibodies which are generated in vitro using synthetic genes. Recombinant antibodies are an in vitro alternative technology to the traditional hybridomas, therefore do not require animal immunization for their production. Recombinant technologies enable the production of high-quality, homogeneous antibodies with specific properties and functions that can be tailored to different applications. Specific epitopes can be designed and engineered to improve the stability, specificity, and affinity of rAbs. Because of the fast production and high quality of rAbs, making them one of the most important tools in research as well as diagnostics and therapeutics. Recombinant antibodies can be produced in a wide range of formats (i.e. Ig, scFc, Fab, etc.), which enables researchers to use the most suitable form for their application and rAbs, like classical monoclonal antibodies, can be used in all research applications, such as immunohistochemistry, western blotting, and flow cytometry. As technology and techniques in genetic engineering continue to advance, the potential applications and impact of rAbs are expected to grow significantly in the future.

Qyaobio possesses extensive expertise in the field of recombinant antibody production. We can provide an immortal supply of consistently high performing antibodies.

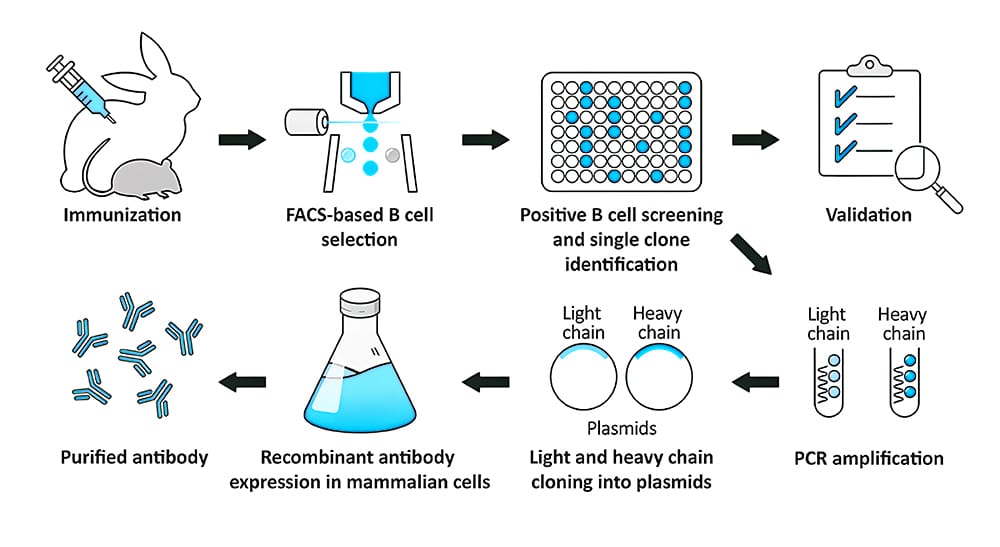

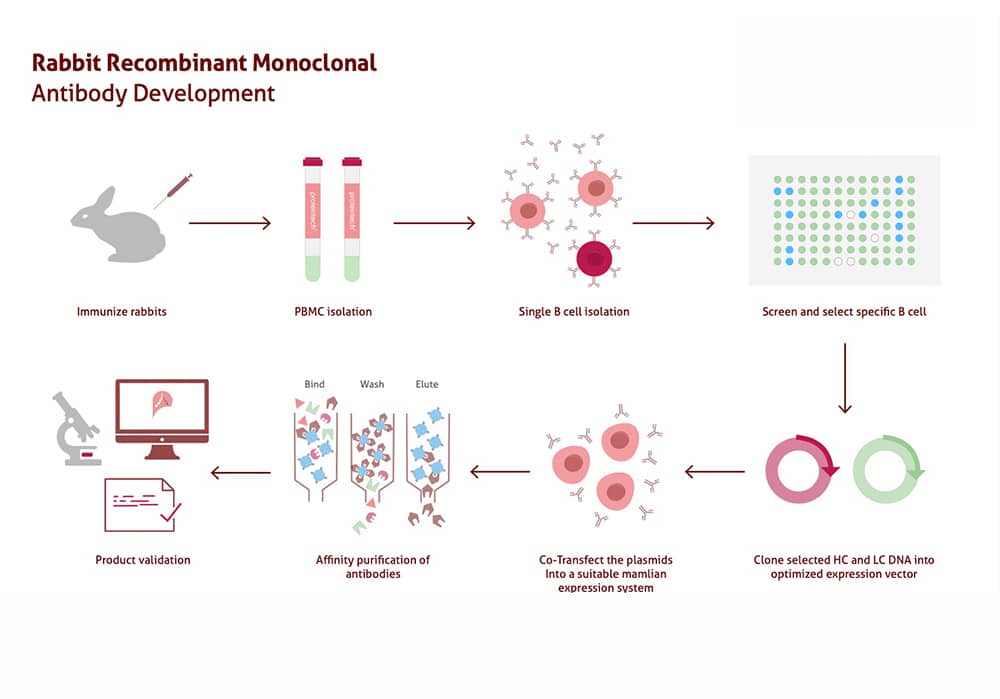

RAb Production Process

In the production of RAbs, the gene encoding for the desired antibody are cloned and expressed in a bacterial or mammalian cell expression system. The genes that encode the heavy and light chains of a desired antibody are cloned into an expression vector, which is subsequently transfected into an appropriate host cell line. The host cells produce and secrete the antibody that can be purified and used for various applications, such as diagnostic assays or therapeutic treatments. Mammalian cell lines are most commonly used for rAb production, but cell lines of bacterial, yeast, or insect origin are also suitable.

RAb Production Steps

There are several steps in recombinant antibody production. These steps typically include:

- Identification of target antigen: The first step in rAb production is to identify the target antigen that the antibody will be designed to recognize and bind to.

- Construct of antibody library: After the target antigen has been identified, an antibody library is constructed that contains a collection of different fab fragments, each with a unique sequence that recognizes the target antigen.

- Screening for antibodies: Using techniques such as phage display or yeast display, the antibody library is then screened to identify fragments, which can specifically bind to the target antigen.

- Antibody engineering and optimization: Once identified, antibodies can be engineered and optimized to improve their stability, specificity, and affinity for the target antigen utilizing techniques such as site-directed mutagenesis or antibody fusion.

- Expression and purification of antibodies: The final steps in recombinant antibody production are expression and purification of the recombinant antibodies to meet various applications. This can be accomplished by the use of bacterial or mammalian cell expression systems, as well as chromatography-based purification.

Antibody Engineering and Optimization

Antibody engineering and optimization is a critical step in rAb production, since it allows for the creation of antibodies with better properties for a variety of applications. Typically, genetic engineering techniques are used to modify the sequence and structure of the antibody molecule in this step.

Antibody engineering and optimization involves several strategies, including:

Antibody Humanization

In order to enhance the immune response, the antigen is typically mixed with an adjuvant such as Freund’s adjuvant. The adjuvant will assist to stimulate the immune system, and result in a stronger antibody response.

Affinity Maturation

Antibodies gain increased affinity, avidity, and anti-pathogen activity in affinity maturation process. It involves the optimization of the antibody’s binding affinity for its target antigen. This can be achieved by introducing mutations into the antibody sequence, in order to enhance its interaction with the antigen.

Bispecific Antibody Production

Bispecific antibodies have two distinct binding domains that can bind to two antigens or two epitopes (an antigen part) of the same antigen simultaneously. This can be achieved through the fusion of two different antibody fragments or bispecific scaffolds.

Antibody Fragment Engineering

Antibody fragments are smaller antibody molecules that retain the antigen-binding properties of the full-length antibody. Antibody fragment engineering entails the modification of the fragment sequence to improve its stability, specificity, and affinity.

Antibody Fusion

Antibody fusion is the fusion of an antibody molecule with another protein or peptide, in order to create a molecule with new properties. An example of antibody fusion is the creation of immunoconjugates, which combine the targeting properties of an antibody with the medicinal properties of a drug.

Overall, antibody engineering and optimization can greatly improve the efficacy and safety of rAbs for a wide range of applications. The modification of antibody sequence and structure can be used to produce molecules with enhanced stability, compatibility, specificity, and affinity for the human immune system.

RAb Advantages & Limitations

Recombinant antibodies provide several important advantages compared to classical antibodies, particularly in terms of scalability, reproducibility, and versatility, making it a promising alternative to traditional methods of monoclonal antibody production.

Advantages

- Superior lot-to-lot consistency: Recombinant antibody production involves sequencing of the light and heavy chains, it’s highly consistent, reliable, and easily reproducible. This also eliminates the problems of cell-line drift and mutations in classical hybridoma production and storage.

- Easy engineering and optimization: Recombinant antibodies can be easily engineered and optimized to improve their binding affinity, specificity, and stability.

- Scalability: Recombinant antibodies are produced in vitro, hence, we can generate them in large-scales. Moreover, since the rAb sequence is known, continuity of supply is assured. This may be an especially critical factor in supporting large, long-term studies.

- Animal-free manufacturing: Recombinant antibodies can be produced without using any animals in the process. This obviates the numerous ethical and animal welfare concerns in traditional monoclonal antibody production.

- Improve tissue penetration: The size of the rAbs can be smaller. Therefore, they exhibit better tissue penetration, blood clearance, and shorter retention time in non-target tissues.

- Versatility: Recombinant antibodies can be engineered to have various formats and properties, such as bispecific or multi-specific antibodies, antibody-drug conjugates, and immune checkpoint inhibitors.

Limitations

- Complexity: The production of rAb is a complex process, which requires highly training and experienced technician, and specialized equipment.

- Cost: Due to the specialized equipment and expertise of rAb, its development and production costs can be high.

- Production time: The production of rAb can be time-consuming, ranging from several weeks to several months, depending on the service provider.

- Protein aggregation: Recombinant antibodies can be prone to aggregation, which can reduce their efficacy and stability.

RAb Expression Systems

Recombinant antibodies can be expressed in different cell systems, including bacteria, yeast, and mammalian. The choice of expression system depends on several factors, such as the desired antibody format, expression yield, and post-translational modifications required for functionality. The plasmids used for antibody production can also impact the expression and purification process.

Expressed rAbs also need to be purified, characterized and validated.

- The methods of purification: Chromatography, ultrafiltration, and precipitation.

- Characterization techniques: ELISA, Western blotting, and flow cytometry.

The following is a comparison of the expression systems of several recombinant antibodies:

| Expression systems | Advantages | Shortcoming |

| Bacterial (E.coli) | low cost, high yield, ease of use. | Not be suitable for antibodies requiring post-translational modifications, such as glycosylation. |

| Yeast (Saccharomyces cerevisiae) | Higher expression yield than bacterial systems. Can perform some post-translational modifications, such as disulfide bond formation. | Unsuitable for antibodies that need complicated glycosylation |

| Mammalian (HEK293、CHO) | Cell lines of choice for glycosylated antibodies, the closest approximation to the native human system. High biological activity and stability. | More expensive and time-consuming than bacterial or yeast systems. |

| Transient and stable expression | Transient expression: faster and easier Stable expression: higher expression yields | Transient expression: lower expression yieldsStable expression: a longer lead time, more complex production process |

Competitive RAb Service

Qyaobio provide recombinant antibody production services to global customers. Our services span from synthesis, cloning and transformation, plasmid preparations, expression development, purifications and removals, and our comprehensive quality control analysis approach. Our one-stop solution can satisfy to your specific needs, ensure the seamless and efficient process from start to finish.

Call Us

+86(021)-50795728

+86(027)-60707970